RECO MACHINES FOR WATCH SERVICING & REPAIRS

RECO machines are integral to the watchmaking industry, enabling watchmakers and jewellers to service and repair high-end watches to exceptional standards. With RECO, highly skilled operators can restore accuracy and finish the most intricate of components with unparalleled precision, ensuring any watch they handle always keeps perfect time.

RECO machines’ applications include felt polishing, buffing, drilling, brushing, chamfering, lapping, grinding, satin-finishing, emery-polishing, and deburring – capable of restoring manufacturer standards. They are trusted by major and world-famous OEMs based in Geneva, Biel, La Chaux-de-Fonds, Schaffhausen, and in the UK in the heart of the Chiltern Valley.

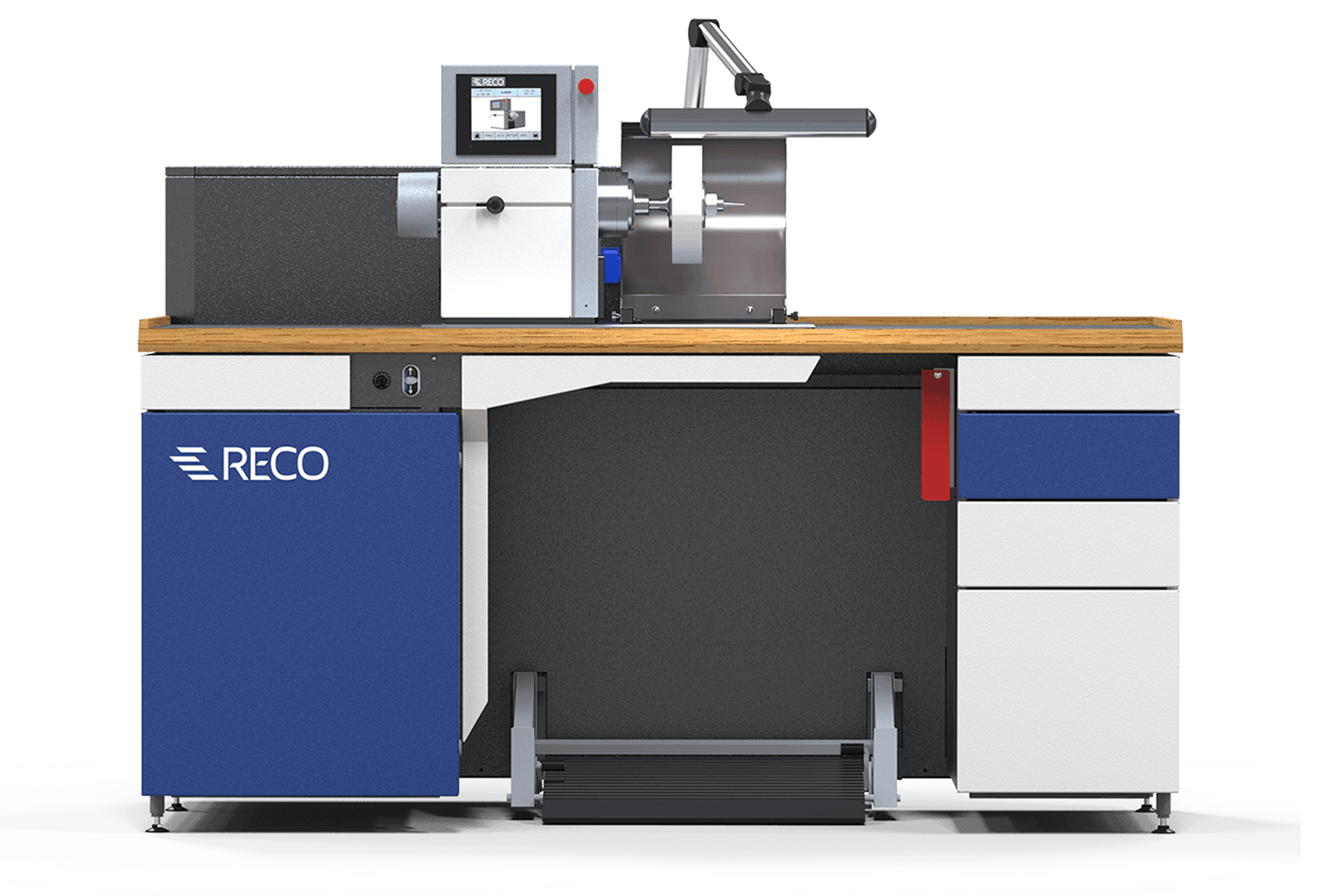

From the BU200/210 for manual finishing to the BP300/310 polishing bench designed for ergonomic working, RECO machines provide everything the modern watchmaker needs to achieve a flawless finish. With years of experience in the watchmaking industry in Switzerland, Mastrini MS Ltd. is best placed to advise your business on the right solution.

WHAT IS THE BEST MACHINE FOR WATCH SERVICING?

RECO is renowned for providing machines capable of maintaining the accuracy and performance of fine quality watches. Whilst many of its machines are suitable for numerous applications, the BU200 and BU210 manual finishing machines are tailored to the watch industry. With a spindle designed exclusively for watchmaking and fine jewellery, these universal machines provide all the tools and accessories required for successful servicing and repair.

These machines can be perfectly integrated with the BP300 or BP310 polishing bench, enhanced by an integrated filtration system and ergonomic design. Together, these technologies allow watchmakers and repair shops to restore timepieces from major manufacturers back to impeccable standards.

For help accessing the right solution for your business, contact Mastrini MS Ltd. Our expertise in Swiss watchmaking and dependable client care means you’ll receive exactly the precision machinery you need to excel. We even offer demonstrations and training in Switzerland, or at your own facility.

RECO BU200/210 MANUAL FINISHING MACHINE FOR WATCH SERVICING

RECO machines are designed and built in Switzerland, meaning precision and quality is part of their DNA. RECO BU200 and BU210 are manual finishing machines equipped to deliver only the highest standards of watch repair, making them essential assets for watch servicing workshops.

The BU200 includes a high precision spindle with Schaublin type W20 collet, manually adjustable feeding speed, and premier quality components with a long service life. The BU210 adds to this the option of manual or semi-automatic work modes, pneumatic quick change of tools for higher productivity, and automatically pre-programmed feeding speed cycles.

At Mastrini MS Ltd., we help our clients access Swiss BU200/210 machines with a dramatically shortened lead time, enabling your watch servicing workshop to bring innovation into the heart of its operation much more quickly.

RECO BP300/310 POLISHING BENCH FOR WATCH SERVICING

A RECO BP300 or RECO BP310 polishing bench has the power to enhance your watch servicing delivery, providing an optimised, highly ergonomic workstation. BP300 is a more economic option, combining high functionality with exceptional aesthetics. The castor feet also facilitate easy handling in the workshop. BP310 builds on these solid foundations by providing an ergonomic, electrically adjustable worktop that enables the modern watchmaker to define their preferred working position.

Mastrini MS Ltd. provides watch machining solutions for the UK and Ireland market, backed up by years of experience in the Swiss watchmaking industry. If you need a polishing bench to define and enhance your servicing, we can supply the right solution with a short lead time and diligent after sales care.

BENEFITS OF RECO BU200/210 FOR WATCH REPAIRS

There are numerous benefits to upgrading your watch repair service with the RECO BU200 or BU210. These Swiss-made finishing machines achieve pinpoint accuracy in the refurbishment of all high-end watch components, including watch case, bezels, watch crowns, bracelets, main plates, and bridges. The machines’ high torque also makes it easy to deliver precision using a range of materials, including stainless steel 316L, gold, platinum, titanium.

They are highly adjustable in terms of feeding speed, with the BU210 even providing semi-automatic and pre-programmed options. BU200/210 are also universal, meaning the machines can accommodate multiple operations, with the setup quickly changed from polishing to lapping to satin-finishing.

The linear cross table, micrometre head, and superior lapping discs are designed to suit customer needs, allowing these robust machines to offer precise and repeatable restorations. With high precision spindles and quality mechanical and electrical components, they achieve the exactitude required by high-end watch servicing workshops.

BENEFITS OF RECO BP300/310 POLISHING BENCH FOR WATCH REPAIRS

RECO BP300 and BP310 polishing benches are invaluable to watchmakers and repair shops. These interlocking benches are highly ergonomic, optimising the workshop space and providing a range of adjustable options for footrest and worktop height. As such, the watchmaker can modify the polishing bench for optimum comfort, facilitating precision and high workmanship over long periods of time.

They also come with an integrated filtration system to combat the dirt inherent in polishing operations. Delivering maximised suction performance with minimal noise, this system dramatically reduces cleaning time, and a quick access dust filter also allows for easy and intuitive maintenance.

Mastrini MS Ltd. is the sole UK and Ireland agent for RECO BP300/310, and can provide you with all the advice, training, and information you need to find the right solution for your business. For more information about the benefits of choosing this advanced polishing bench, don’t hesitate to get in touch.

SPEAK TO YOUR RECO MACHINE SPECIALIST

Watches and timepieces are some of the most precise mechanisms on the planet. To preserve accuracy throughout the service life of high-end watches, only the finest machining technology will suffice. Based in South Wales, Mastrini MS Ltd. is the sole UK and Ireland agent for RECO machines – with second hand machines available for customers on a tight budget or timeline.

We help our customers design their machines according to their needs, and offer demonstrations and training either in Switzerland or their own facility. If a universal machine isn’t the right fit, we can supply a double disc lapping machine which may be more suitable – contact us for further details.

After assessments of existing finishing processes, we will be more than happy to recommend new solutions to reduce machining times and improve the quality of watch servicing and repair you deliver. We also advise on and supply consumables like abrasives and compounds, and provide a diligent after sales service. For watch machining technology that unites productivity and precision, you can count on us.

CONTACT US TODAY!

Discuss your CNC machine tool requirements with Mastrini MS Ltd.

We have the extensive experience and industry knowledge to provide tailored advice and find the ideal solution for your application.