CIPOSA MICRO DISPENSING CENTER

CIPSOA is renowned for providing machines capable of maintaining the accuracy and performance required for the manufacture of small and complex medical devices. Whilst many of its machines are suitable for numerous applications, the CIMED-SB, Micro Dispensing Smart Bench is tailored to the manufacture of precision medical devices. With a dispensing head mounted on a up to 5 axis gantry, the CIMED-SB is designed exclusively for micro dispensing applications of complex surfaces like stents. This machine based on Ciposa’s standard Smart-Bench platform provides a reliable, flexible and scalable solution for the Med-Tech industry.

For help accessing the right solution for your business, contact Mastrini MS Ltd. Our expertise in the assembly of medical devices means you’ll receive exactly the precision machinery you need to excel. We even offer demonstrations and training in Switzerland, or at your own competence center.

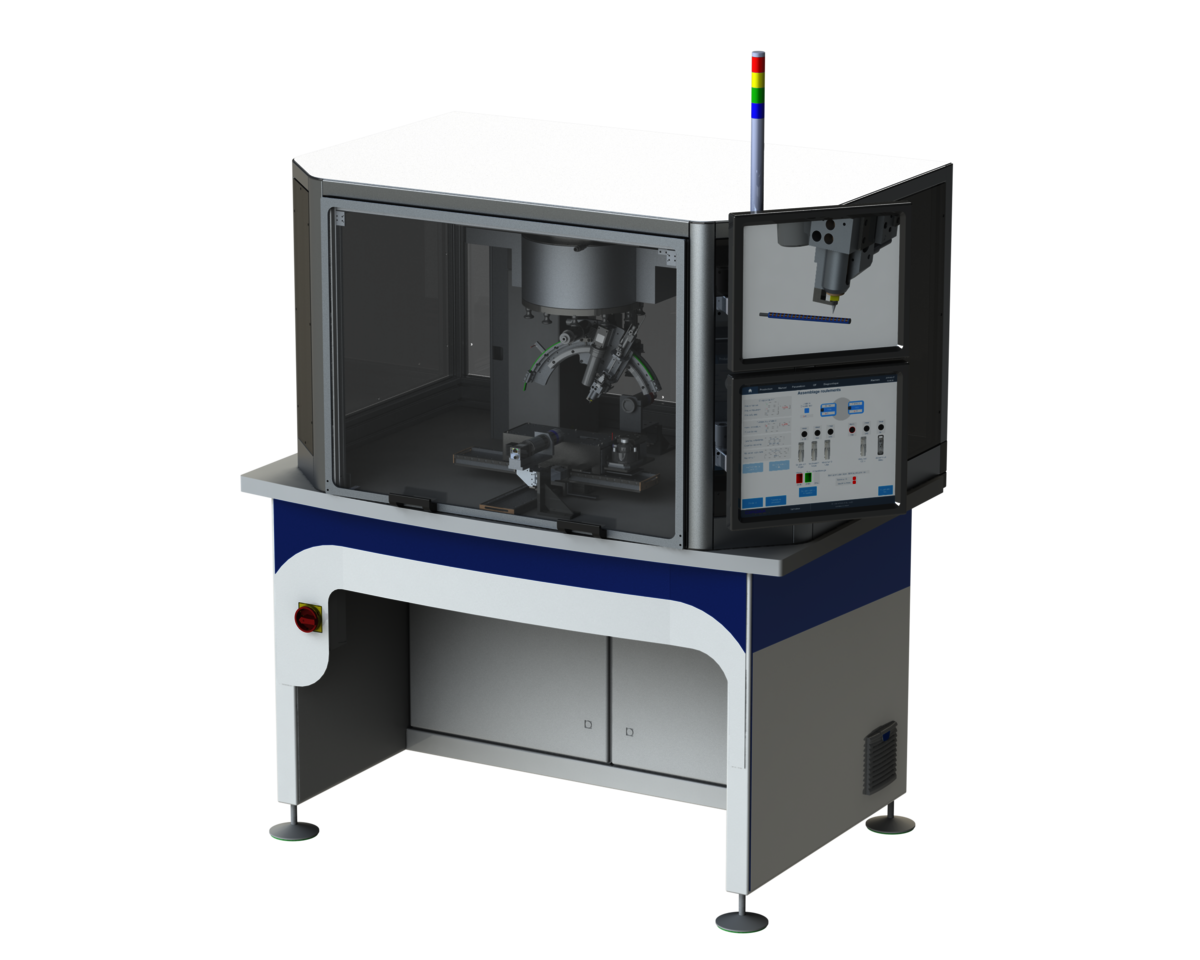

CIPOSA SMART BENCH DISPENSING

Vision system embedded on the dispensing head to ensure:

- Components recognition/control before picking.

- Acquisition of X and Y positions of the components.

- Micro-Dispensing head servo-control.

- Final dispensing control > quality and quantity.

Laser sensor on Z axis for components heights acquisition.

Final positioning repeatability on all axes ≤ ±10 μm.

Highly accurate and repeatable dosing down to nanoliter scale.

Wide range of dispensing systems available:

- Time/pressure.

- Jetting.

- Volumetric.

Minimum volume = 1.0 nL, with dosing repeatability ≤ ± 5.0%.

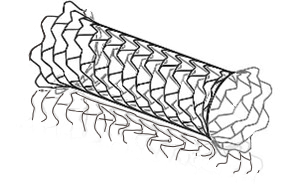

OVERVIEW OF STENTS

A Stent is a small, expandable wire-mesh structure device in Inox 317L, Cobalt Chrome, Plastic or biodegradable material that treats coronary heart disease and other diseases in which vessels are clogged, by re-opening narrowed arteries.

Stents implantation is a common procedure, a stent is mounted on a balloon catheter and then introduced through the area of obstruction in an artery. The balloon is inflated to widen the vessel and relieve the blockage. The stent, now against the vessel wall, is working as a scaffolding and the balloon is deflated and retracted, leaving the stent behind. Some stents are also self-expandable, whit deployment activated by the surgeon with a mechanism using the delivery system.

The first stents were bare metal stents (BMS) and despite improvements on the design, material and introduction techniques, BMS were facing high in-stent restenosis, which occurred in 10-30% of all stents. Restenosis is the term used when an “unblocked” vessel is “blocked” again after the procedure, usually within the first year.

The introduction of drug-eluting stents (DES) in the early 2000’s was to address the issue of restenosis. A polymer and a drug is applied to the stent strut that will help reducing the rates of repeat revascularization. The polymer, attached to the drug, serves as a barrier so the drug can be released over a period of time, generally months.

DES or third generations stents relies on manufacturing methods like ultrasonic spray coating, dipping, air brush and deposition on the stent struts. The challenges that stent manufacturers are facing are complex because the solution must be applied with accuracy, repeatability and homogeneity. Furthermore, the process must be perfectly controlled to meet medical standards.

SPEAK TO YOUR CIPOSA MACHINE SPECIALIST

To preserve quality and accuracy throughout the lifecycle of your medical device, only the finest machining technology will suffice. Based in South Wales, Mastrini MS Ltd. is the sole UK and Ireland agent for CIPOSA machines.

We help our customers design their machines according to their needs, and offer feasability studies and training either in Switzerland or their own facility. If a standard platform machine isn’t the right fit, we supply bespoke machines – contact us for further details.

CONTACT US TODAY!

Discuss your CNC machine tool requirements with Mastrini MS Ltd.

We have the extensive experience and industry knowledge to provide tailored advice and find the ideal solution for your application.