Process Consultation.

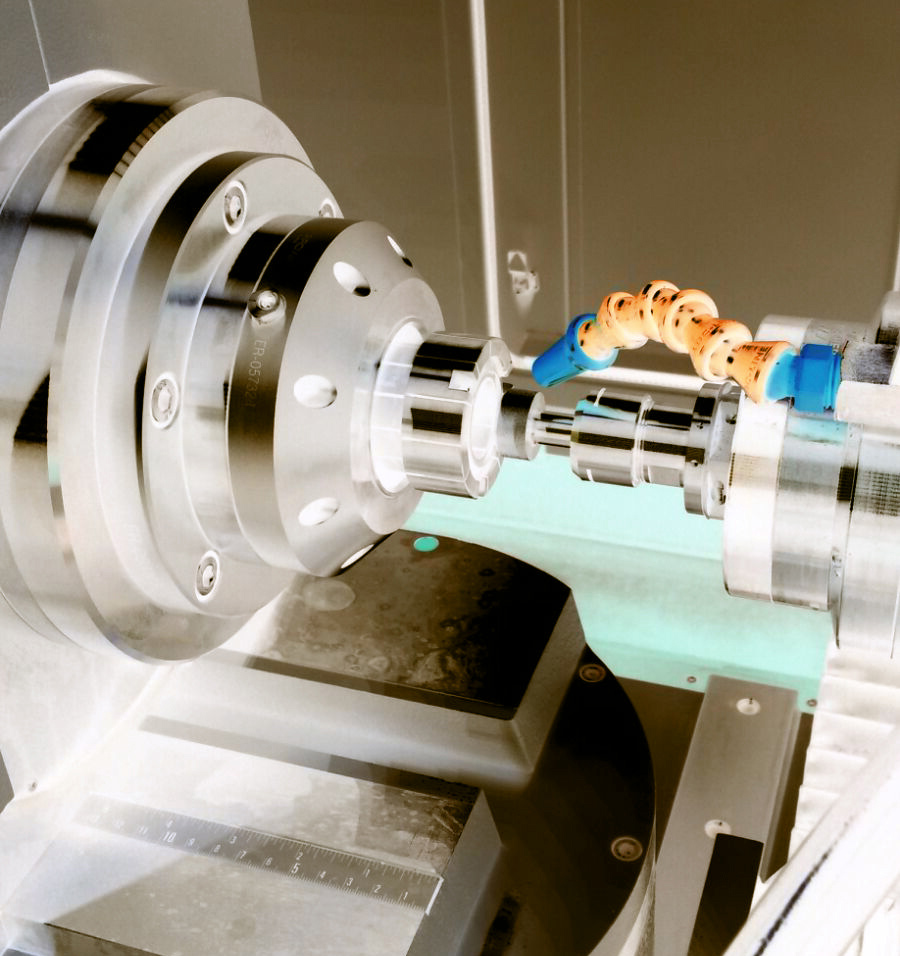

We have focused our expertise in precision grinding and work with the best machine tools’ manufacturers, independent consultants and innovation centres to evaluate and troubleshoot grinding problems.

Mastrini MS Ltd can help you to improve your processes, increase your capacity, reduce your lead time & time to market so you can take more opportunities and be more competitive on your market.

Over the years we have gained a deep understanding of grinding technologies; we work closely with Swiss experts that provide unique and innovative solutions for our customers. The partnership we have built overseas enables us to have a different perspective than our competition and generate unique ideas for the British market.

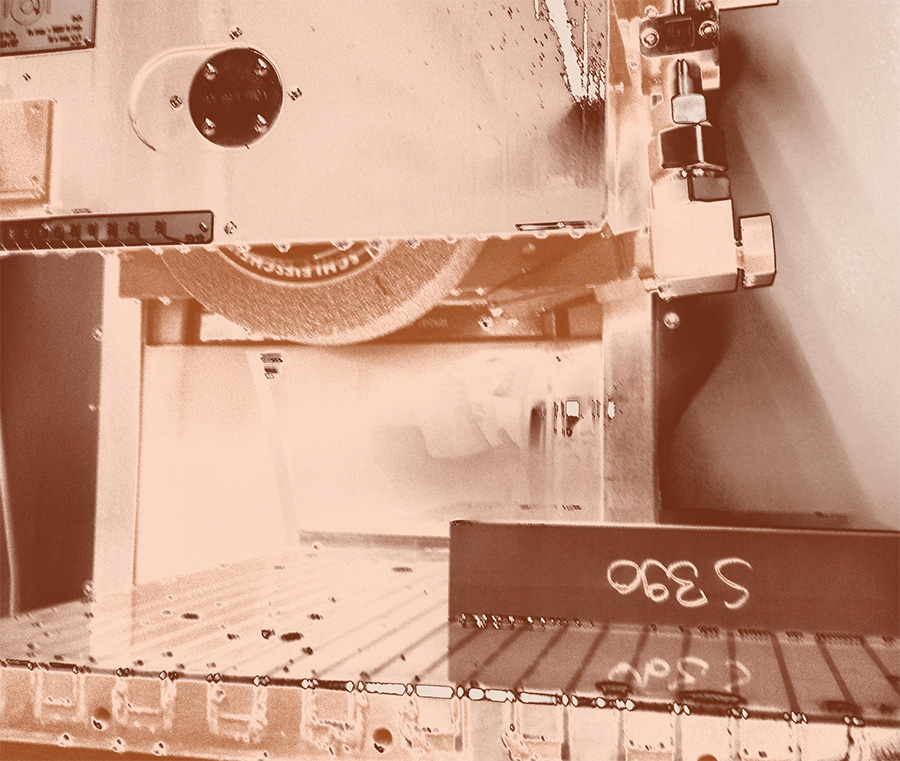

When a client contacts us to optimise its process, we work with them, internally and with our partners, to understand their problems so we can propose improvements and reach new standards. We map their process, look for weaknesses within the added value chain of the product and, with systematic methods like design of experiments (DOE), we use data and information to find the best available

solutions.

Problems experienced can include:

- Thermal damage

- Vibration and Chatter

- Surface roughness “orange-peel”

- Loss of accuracy – Roundness and problems achieving precision tolerances

- Wheel glazing

- Wheel wear

- Dressing tool wear

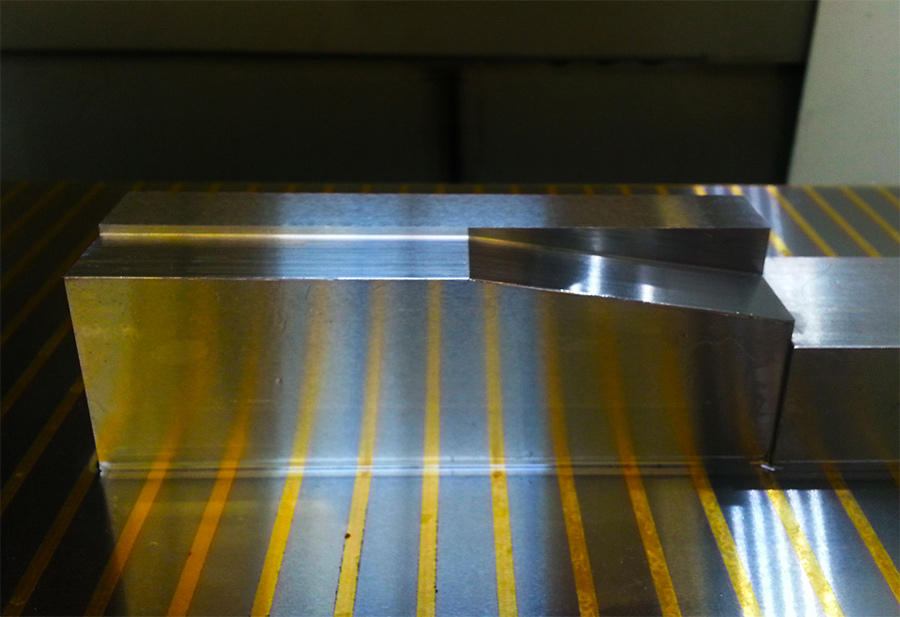

The quality of the incoming workpiece is crucial and will determine the process efficiency and conditions of the final product.

If you need more information on our Benchmarks Studies please contact us.