Feasibility Studies.

Available technologies and markets are constantly changing, and new challenges can bring uncertainties. Mastrini MS Ltd can help you mitigate the risks and meet your objectives through technical and financial feasibility studies.

Our complete feasibility studies help our customers make their decision before an investment and assess the viability of their projects, as well as potential opportunities and problems that will need to be overcome.

Whether the objective is to increase production capacity, optimise surface finish, improve grinding efficiency and profitability, compare additive manufacturing technologies, or integrate automation, we have the expertise to provide a complete analysis necessary to ensure our customer make the right decision and meet their objectives.

- Scope: Audit additive manufacturing technologies available on the market using plastic material.

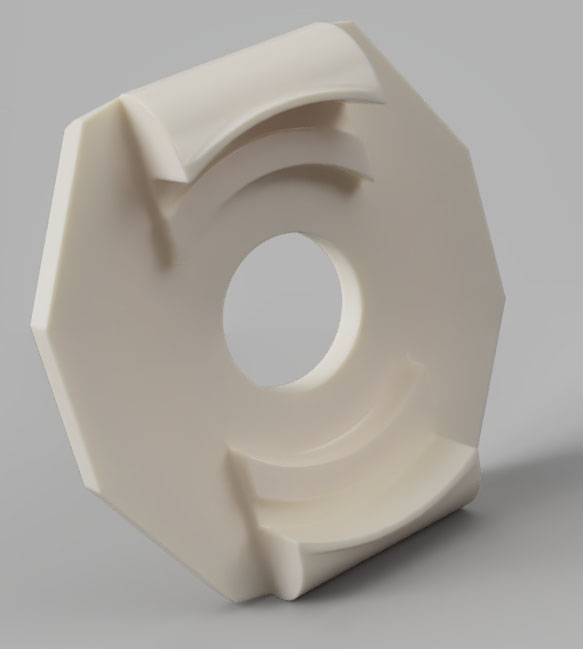

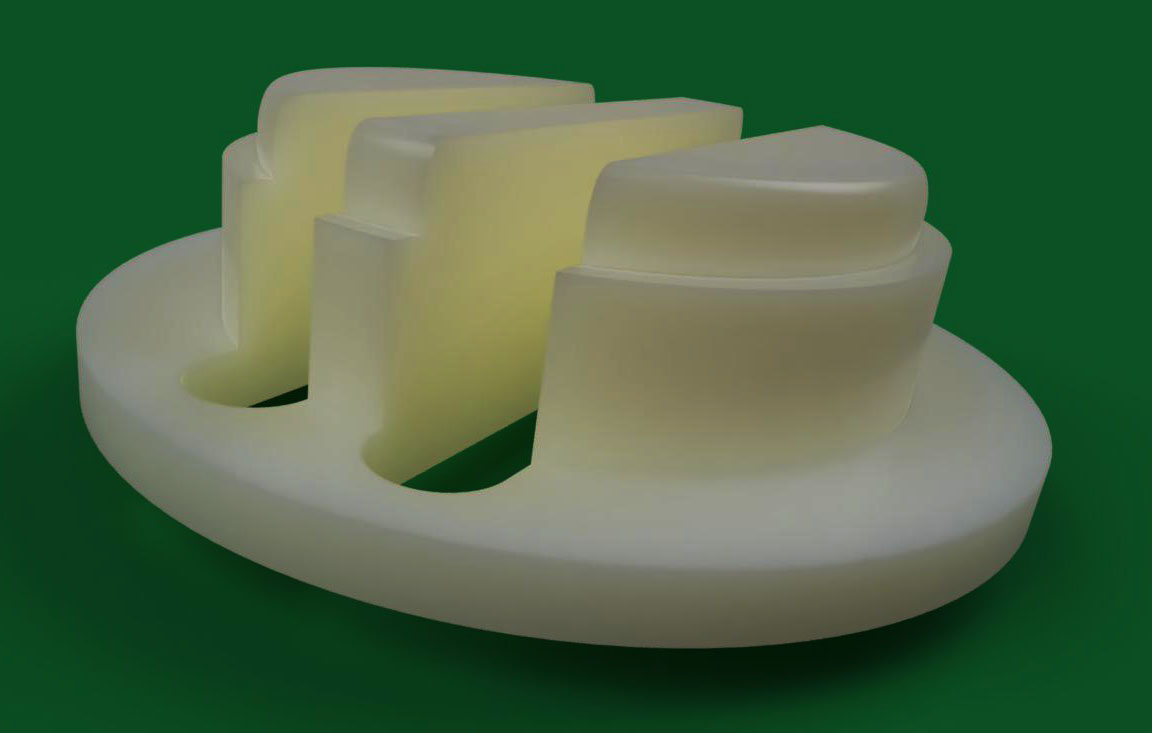

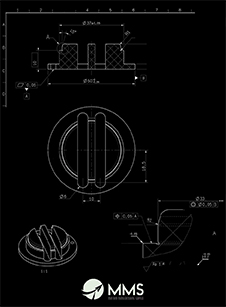

- Parts: Automatic workholding fixtures used in harsh environment automated cells.

- Annual Volume: 20 000pcs 50 different geometry and material used.

- Sector: Medical and Automotive.

- Geometry:

- Tolerances min +/- 0.03mm

- Surface roughness min Ra 1.6

- Mechanical Properties:

- High abrasion resistance

- High temperature resistance

- Hardness up to Shore 65D.

Case study scenario.

The Engineering Director of this medium company needed quick results and was looking for a comprehensive report on the feasibility for the introduction of a new equipment before the deadline of his company’s budget vote.

We were able to demonstrate that back in 2018, the 3D printing market didn’t have enough maturity to provide a solution that met all requirements of the given specifications. Nearly 40% of the annual volume could have been manufactured in 3D printing as a replacement for traditional machining techniques but this was not enough to defend an investment for the next financial year in front of its stakeholders.

6

Number of suppliers that signed up for the challenge.

120

Parts printed and submitted to MMS Ltd for mechanical testing and geometrical inspection.

45

Parts submitted to the client.

17

Materials used.

5

Technology used (FDM – SLA – DLP – SLS – Polyjet).

2

Months to complete the study.

Today high-performance thermoplastic like PEEK can be used in powder-based solution for the SLS process, 3D printing is a fast-moving technology. Frequent benchmarks are essential if you want to stay at the forefront of your market.

Benoit M.

If you need more information on our Benchmarks Studies please contact us.